Diamond Powder

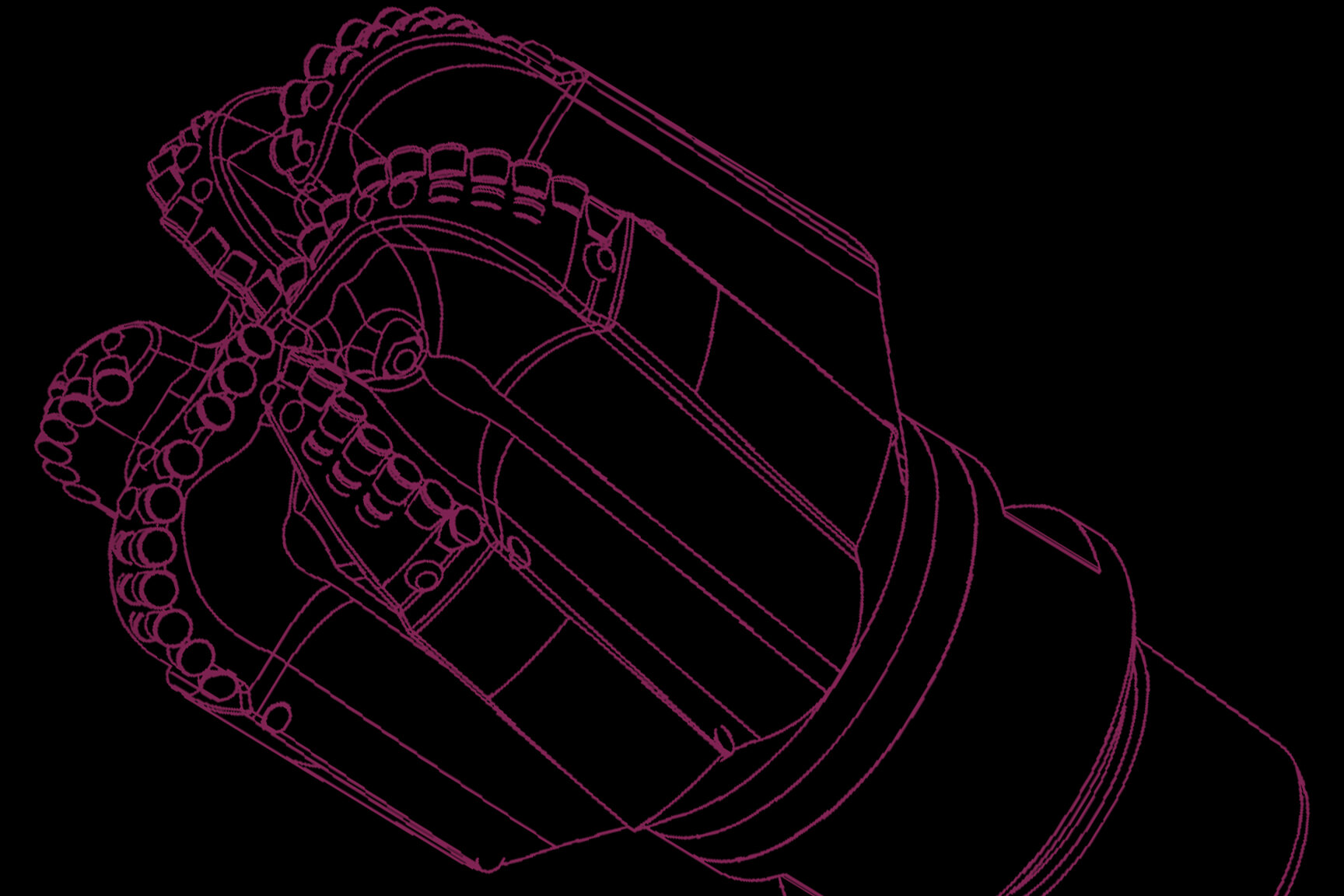

Diamond powders are a popular abrasive material due to the material’s high internal strength and toughness. They are used in a variety of applications including lapping or polishing of hard materials, in saw blades for cutting stone and concrete, in grinding wheels used in the automotive and aerospace industries, and in drill bits used in mining, and oil and gas exploration.

Mesh Diamond

Mesh diamond or saw grit is typically coarser diamond crystals used in applications requiring more aggressive abrasive action. It comes in a variety of grades that define the shape, toughness, and friability of the crystals. Sizing is accomplished through running the material through mesh sieves thus the description as mesh diamond.

Lapping Grade – Diamond with irregular shapes with low toughness/high friability. Economical with good properties allowing the crystal to breakdown and polish, or smooth out hard material surfaces.

SMB 40-60 – Diamond with semi-irregular shapes and lower intrinsic toughness; excellent value for less demanding abrasive applications.

SMB 70-80 – Diamond with semi-blocky crystals with angular shapes and medium toughness. Perfect for applications where you need your crystal breakdown to accomplish your task but still want to extend the life.

SMB 90-100 – Diamond with strong, blocky crystals and lower levels of inclusions; ideal for the most demanding applications requiring long diamond life.

Diamond Micron Powder

Diamond micron powders are ultrafine diamond crystals micronized into tight particle size distributions for use in various applications including polishing and lapping, fine grinding, and even sintering into polycrystalline diamond compacts. Sizing is in micron particle size distributions that can be geared towards your application’s requirements.