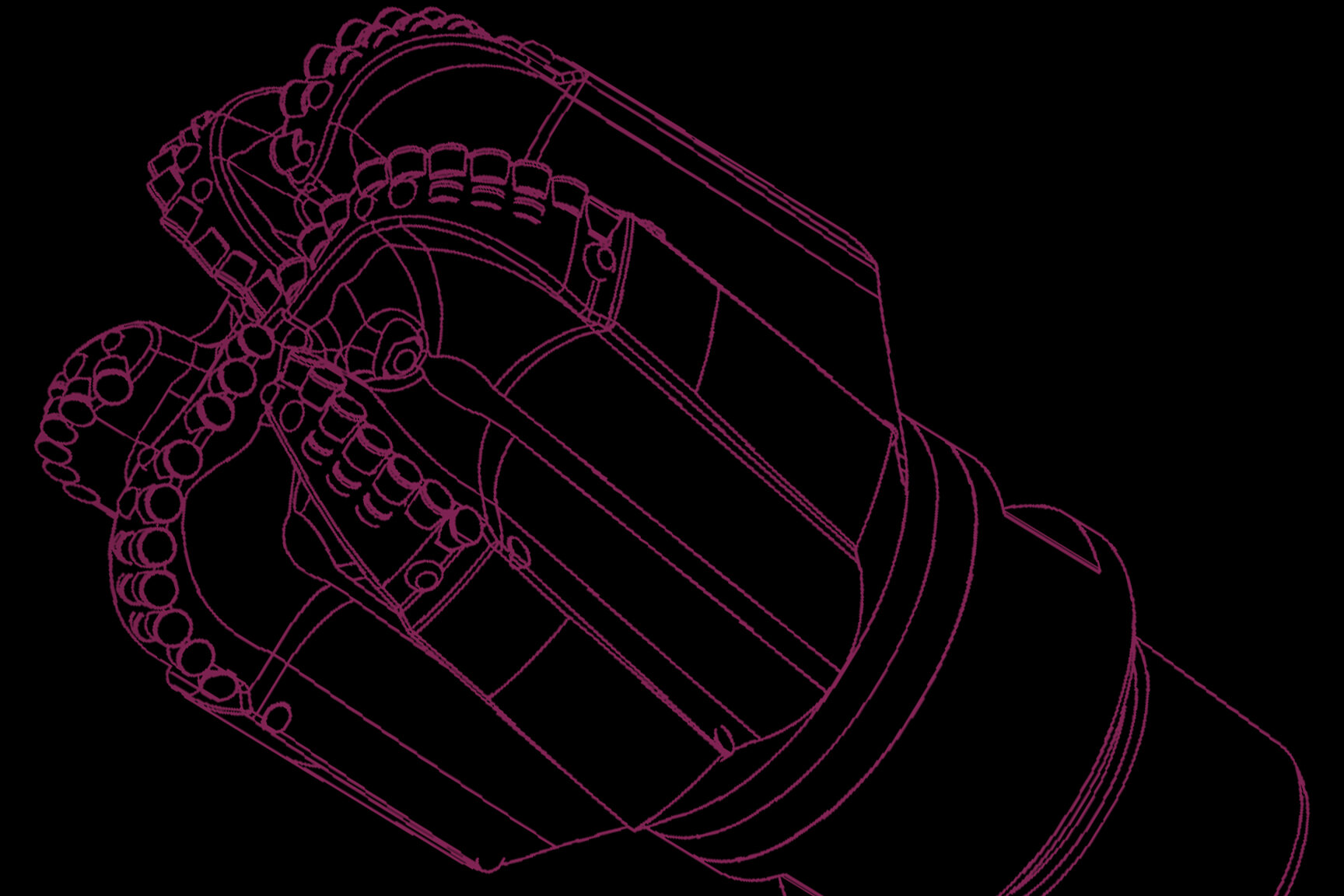

PDC Leaching

Our proprietary PDC leaching process is an affordable approach to making PDC products more resistant to the abrasive wear caused by hard rock drilling, wire drawing, and other demanding PDC applications.

IDS’ leaching process chemically removes the cobalt catalyst from a PDC microstructure. The result is a diamond table with improved resistance to thermal degradation and abrasive wear, resulting in a longer useful cutter life.

PDC Recovery

We have been involved in reclaiming dull or used PDC cutters for over 15 years. During that time, we have perfected our processes to ensure our customers receive a fully qualified cutter to meet their requirements.

We can also re-work your reclaimed PDC cutters with excessive wear by reducing the diameter and re-finishing the part to like new standards

Our recovery range of services includes:

PDC Cutter de-brazing from used bits

PDC Cutter clean-up including complete braze removal

PDC Cutter re-qualification

Die-Penetrant inspection for detecting microfractures or thermal damage

Visual inspection to wear specifications

Testing to determine whether a cutter is leached