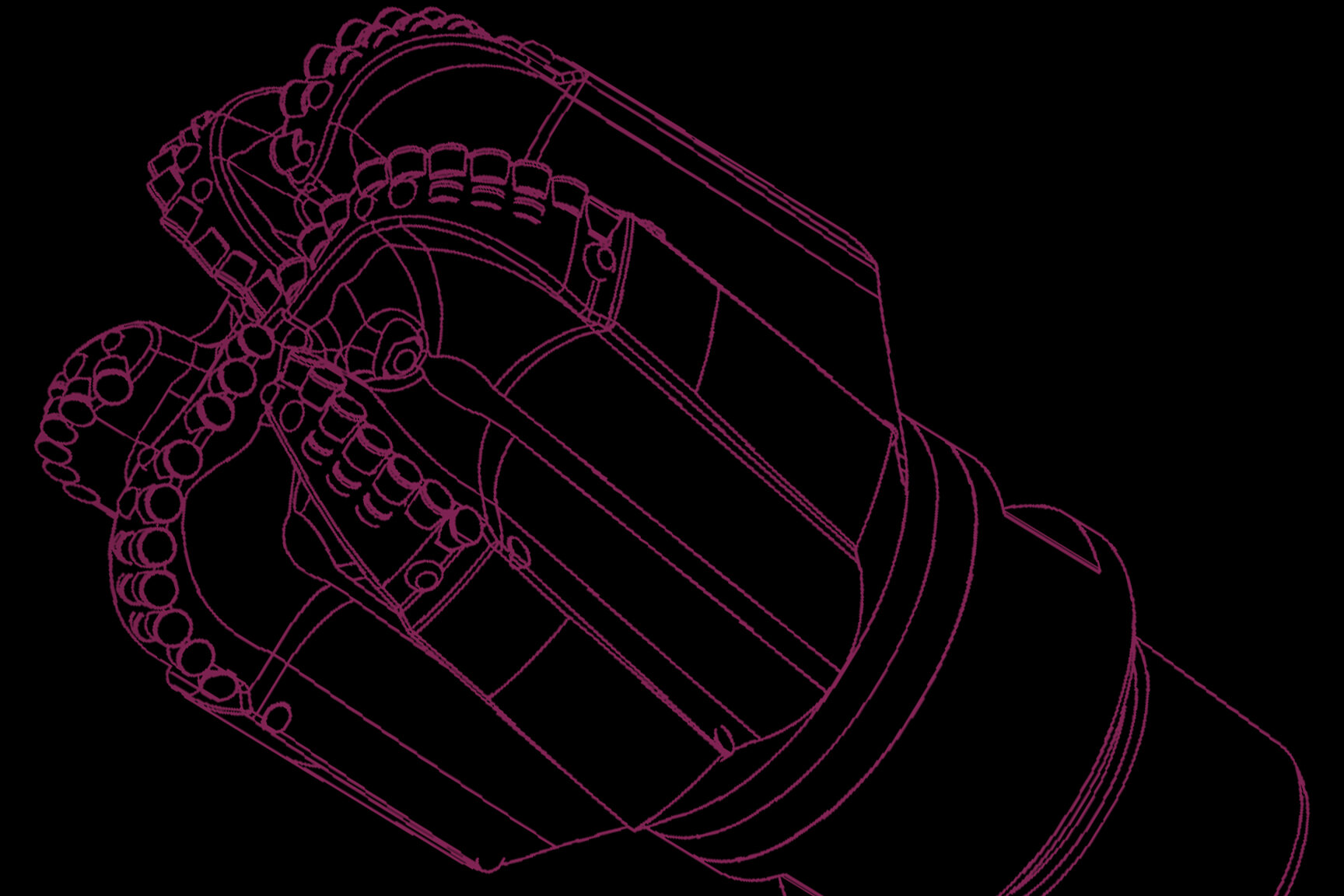

PDC Fabrication

PDC is a versatile material with applications as varied as drilling for oil, machining aluminum and wood, and cutting stone or concrete. It is composed of diamond particles grown together with the help of a sintering catalyst, usually cobalt. While diamond has properties such as mechanical strength, wear resistance, and uniform hardness, cobalt allows the material to be cut with a wire electro-discharge machine (EDM). PDC surfaces can also be polished, shaped, and sharpened using super-abrasives grinding wheels. The shaping of the PDC diamond table and substrate can be altered by means of near net pressing, laser modifications, or grinding equipment. IDS can modify the geometry of each specific shaping method within the tolerance specifications of the customer.

PDC’s flexibility allows it to be used for a wide array of applications. We offer a variety of standard products made from polycrystalline diamond, but we can also manufacture custom parts to meet your needs.